EMI/RFI Shielding

Our MicroGrid® expanded metal foils protect critical aerospace, medical, and automotive electronics from electromagnetic interference.

Dexmet MicroGrid® EM Products and PolyGrid®

|  |

Why Dexmet Solutions are Optimal for EMI Shielding

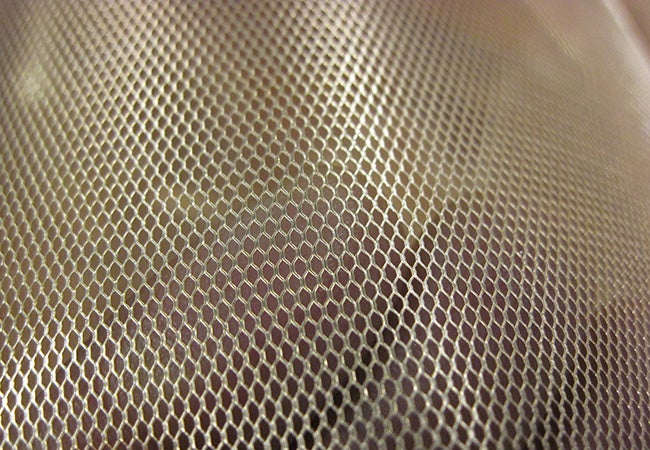

The Dexmet® MicroGrid® EM series of expanded metal foils are versatile, effective materials for shielding against electromagnetic interference (EMI). Expanded metal foils are formed from solid metal foil in a proven, economical “slit-and-stretch” process. They are electrically continuous and, unlike knit or woven meshes, exhibit consistent and predictable conductivity.

Thin, strong, flexible and lightweight, expanded metal foils will not fray or unravel, and conform readily to complex surfaces, making them well-suited to composite manufacturing processes.

Standard configurations include copper, aluminum, nickel and Monel meshes at .002 and .003″ thick (50 and 75µm). Dexmet can readily produce custom types using other metals and foil thicknesses, including Cu and Al types down to .001″ (25µm). The open area of the mesh can be precision-tailored to meet user requirements for weight, resistivity, formability and shielding effectiveness.

Applications:

- Shielded enclosures

- Gaskets

- Ventilation screens

- Cable shielding

- Laminated structures

- Cockpit electronics