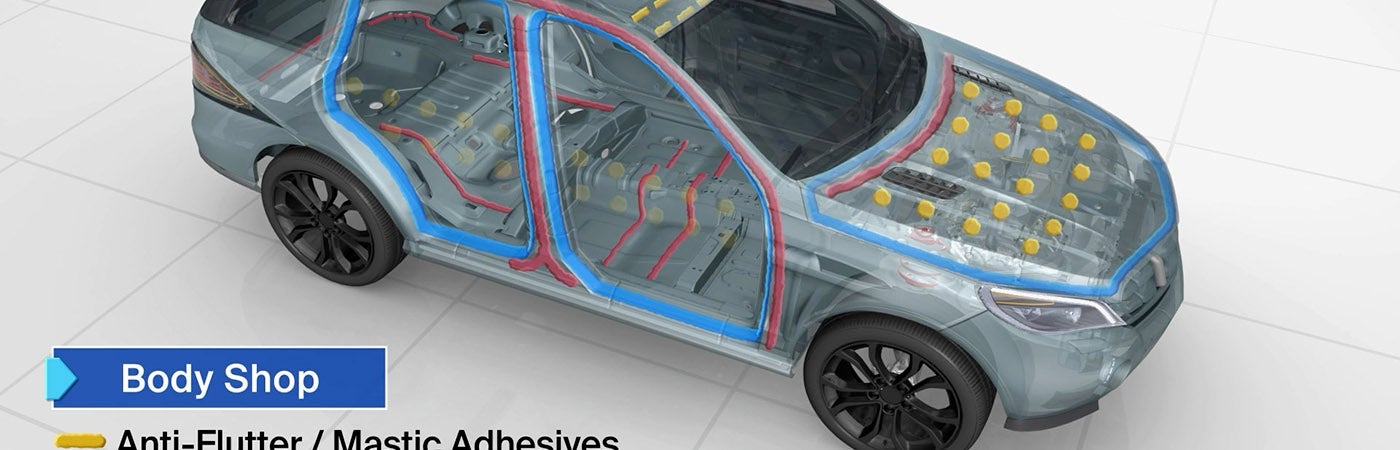

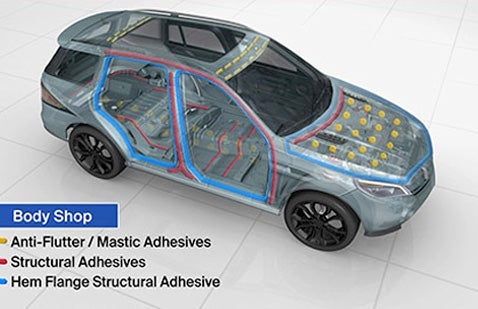

CORABOND® — Anti-Flutter Adhesives

PPG offers highly customized liquid PBD and rubber-based anti-flutter adhesives and sealants for use in a variety of production environments and with multiple substrates.

By eliminating bond-line read-through, CORABOND anti-flutter adhesives enable OEMs to further reduce vehicle weight and cost through the use of thinner gage metals. Each product (high to low expansion) offers exceptional wash-off, sag and corrosion resistance with optimized application energy utilization.

Recent PPG innovations include sulfur-free and ADCA-free anti-flutter chemistries as well as a

high-expansion acoustical anti-flutter.

REVOFORM® — Anti-flutter/Sealer Tapes

Complimentary to PPG CORABOND® pumpable anti-flutter technologies, PPG also offers reactive and non-reactive butyl based part technology . These preformed parts offer good adhesion on oily substrates, provide good wash-off resistance and are compatible with current pretreatment and e-coat systems.

CORABOND® — Structural Adhesives

PPG is a global supplier of structural adhesives technology, enabling OEMs to achieve significant cost and weight savings while addressing a wide range of vehicle design consideration:

• Stiffness and dynamic characteristics

• Sealing performance

• Corrosion resistance

• Wash-off resistance

• Wet adhesion to oily substrates

• Weld bonding; reduction in overall welds

• Low and broad bake capabilities

• Long shelf life

Our latest innovations include a new generation of CORABOND fracture-toughened/crash resistant single-component epoxy adhesives which deform rather than break upon severe impact to enhance energy absorption and improve vehicle safety. These new products can be used for joining multiple materials in body-in-white.

AUDIOGUARD® — Body Shop Technology

Cold-pumpable, reactive rubber-based technologies that can be applied to oily substrates, where localized, high vibration damping is required, such as door, roof and/or side panel applications.

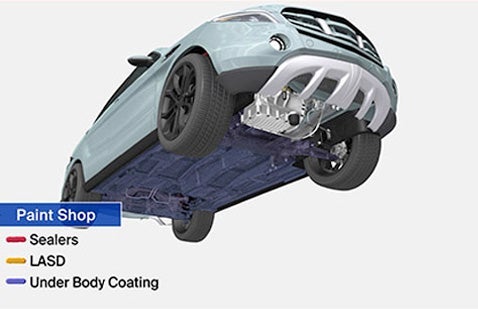

AUDIOSHIELD™ — Constrained Layer Dampener Pads

Complimentary to PPG AUDIOGUARD® liquid applied sound dampeners, PPG also offers constrained layer damping pads that offer a cost and weight competitive technology to reduce road noise and vibrations within the vehicle body. These self adhesive parts offer easy install customized shapes for varying application needs. These non-reactive product can withstand high processing temperatures, enabling flexibility of use in either the body shop, paint shop, trim/assembly or tier application.

Applications:

- Doors

- Quarter panels

- Hoods

- Trunk lids

BPR® — Body Panel Reinforcement (Pumpable)

REVORCE® — Reinforcement Parts

Panel stiffening technology developed to locally reinforce vehicle body panels enabling lightweight though localized panel thickness reductions.

Benefits of PPG BPR and REVORCE Products Include:

- Automated and part portfolio

- Targeted reinforcement enabling light-weighting

- Optimized cost / performance solution