The old way won't cut it anymore.

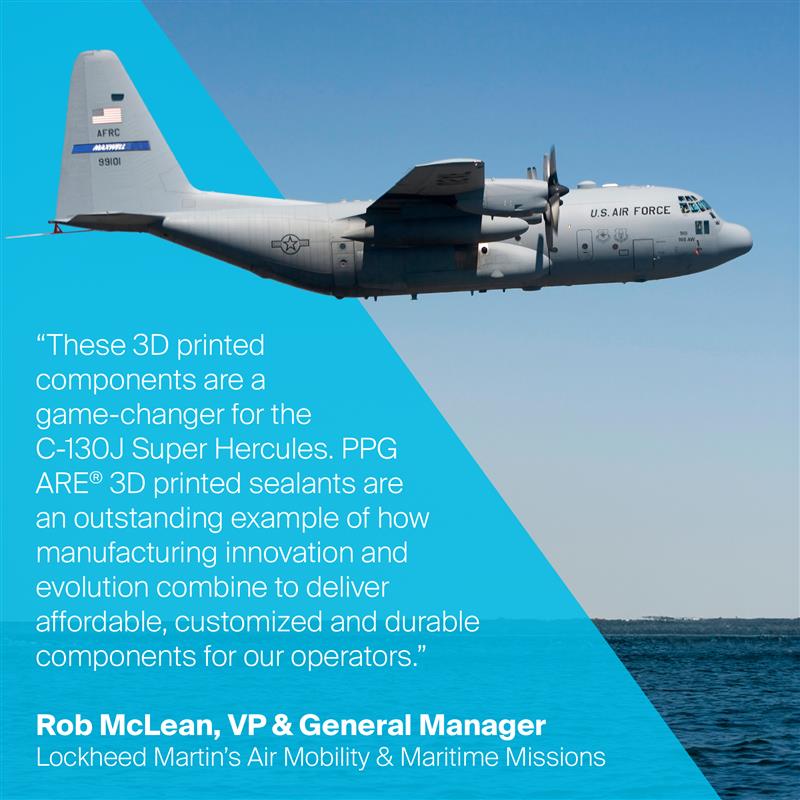

The aerospace industry is booming, driven by pent-up post-COVID demand and soaring volume forecasts. To stay ahead, aircraft OEMs and maintenance professionals must boost productivity and cut costs.

But outdated installation techniques are holding them back.

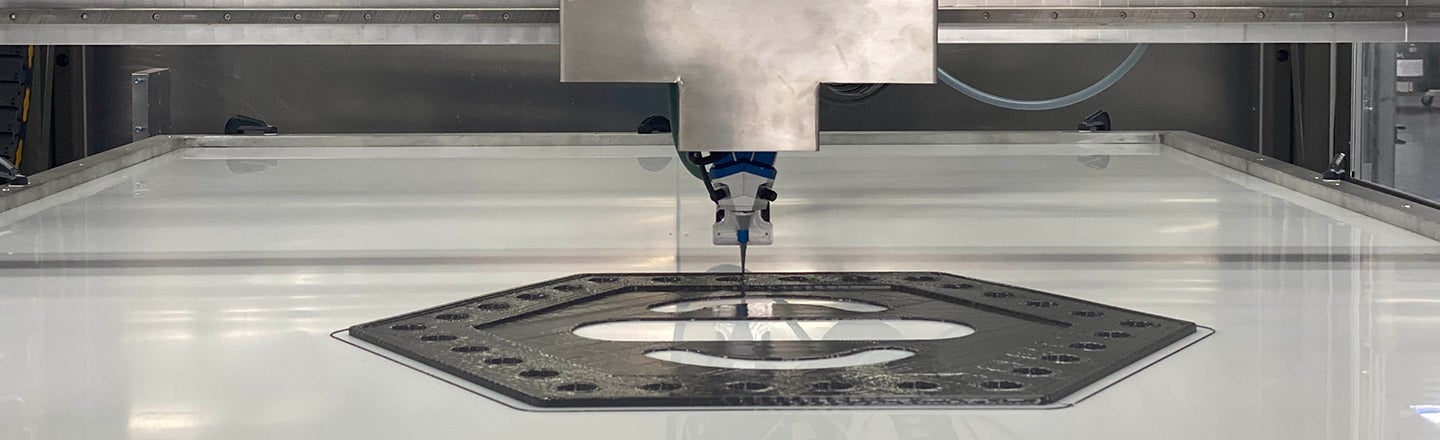

Traditional sealant installation processes are slow and imperfect, resulting in messy work areas and uniforms. Product overage leads to wasted time on re-work, threatening efficiency.