PPG has long been at the forefront of innovation in aerospace materials, including sealants, coatings and transparencies. We recently introduced a transformative capability, 3D printing of our established line of aerospace sealants. This advancement addresses many of the traditional challenges associated with manual sealant application in critical aircraft areas such as fuel tanks, pressure seals, conductive zones, windshields, access doors and high-temperature environments.

Challenges of Traditional Sealant Application

Traditionally, applying aerospace sealants has been a labor-intensive process requiring skilled technicians to manually mix and apply two-part sealants. This method demands significant manpower, careful surface preparation, and generates chemical waste that must be properly managed. Whether mixed by hand or with tools, the process consumes valuable time.

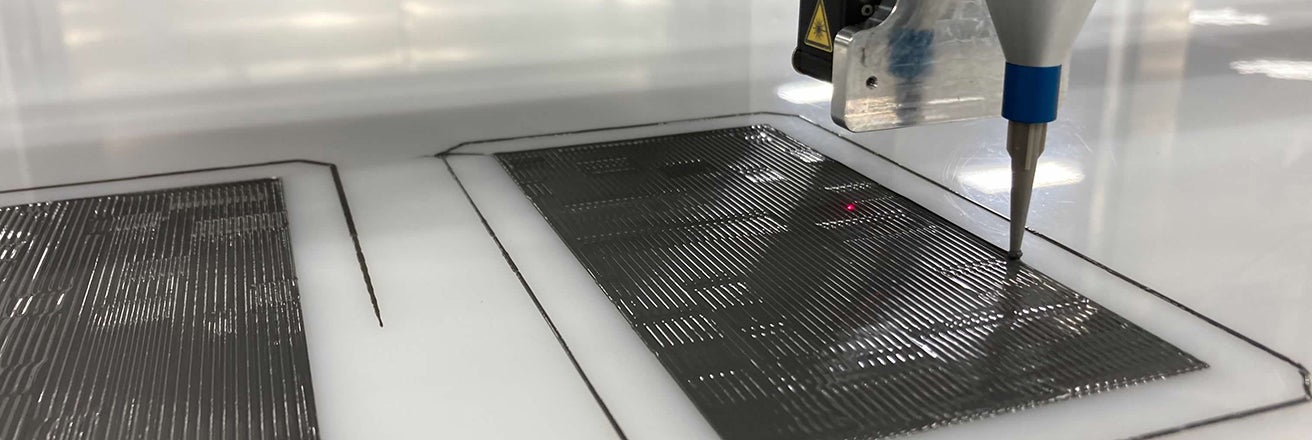

Recognizing these challenges, we developed PPG ARE (Ambient Reactive Extrusion) Technology a proprietary 3D printing process that automates the mixing and application of sealants. This technology statically and dynamically combines parts A and B of the sealant and extrudes the fully mixed material layer by layer onto a print bed, creating a precise, fully cured seal tailored to the specific application.

Operational Benefits of 3D Printed Sealants

The benefits of PPG ARE 3D printing technology are already evident in operational use. For example, a pressure sealing door at an OEM, which previously required approximately eight man-hours and frequent rework after pressurization testing, can now be sealed in just 30 minutes by a trained technician using PPG’s 3D printed seal. This method consistently produces a high-quality seal with a 100% first-pass pressure test success rate at the OEM, eliminating costly rework and reducing aircraft downtime.

The streamlined process helps ensure that each seal is applied with precision, enhancing the overall durability and reliability that is crucial for maintaining the stringent safety standards required in aerospace applications. By simplifying the sealant application process, we help our customers lower the possibility of human error, contributing to the overall integrity and functionality of aircraft components. The efficiency and accuracy offered by this technology not only optimizes resource utilization but also provides operators with the confidence that each aircraft component has been sealed to the highest standards of quality and performance.

Environmental and Safety Advantages

In addition to significant time and cost savings, PPG’s 3D printed sealants help minimize hazardous waste disposal, supporting our commitment to sustainability. The precise application enabled by 3D printing technology ensures that only the necessary amount of material is used, leading to waste reduction. By implementing such efficient practices, we help our customers minimize the environmental footprint of their aerospace manufacturing and maintenance activities.

Our Commitment to Advancing Aerospace Maintenance

PPG continues to lead the aerospace industry by developing innovative solutions that improve safety, efficiency and sustainability. The introduction of 3D printed aerospace-approved sealants through PPG ARE technology marks a major step forward in aircraft maintenance and manufacturing processes. By overcoming the limitations of manual sealant application, PPG delivers a reliable, efficient, and sustainably advantaged solution that meets the evolving needs of OEMs and operators worldwide. As PPG continues to refine our 3D printing techniques, the transformative impact of these innovations becomes increasingly significant across the aerospace industry, underscoring the pivotal role PPG plays in advancing aviation technology.

PPG ARE 3D printing technology provides benefits for diverse aerospace operations, offering a revolutionary approach to sealant application that enhances both efficiency and precision. This pioneering development allows operators to enhance their operational processes through reduced application times and improved seal quality, which are critical in today's fast-paced aerospace industry.

Ready to explore PPG ARE 3D printing technology?

If you are looking to improve your maintenance operations and decrease AOG time, PPG can help guide you on how this cutting-edge technology can be customized to your specific requirements.

To explore how PPG ARE technology can benefit your operations or to discuss specific applications, please contact us or send us an email.