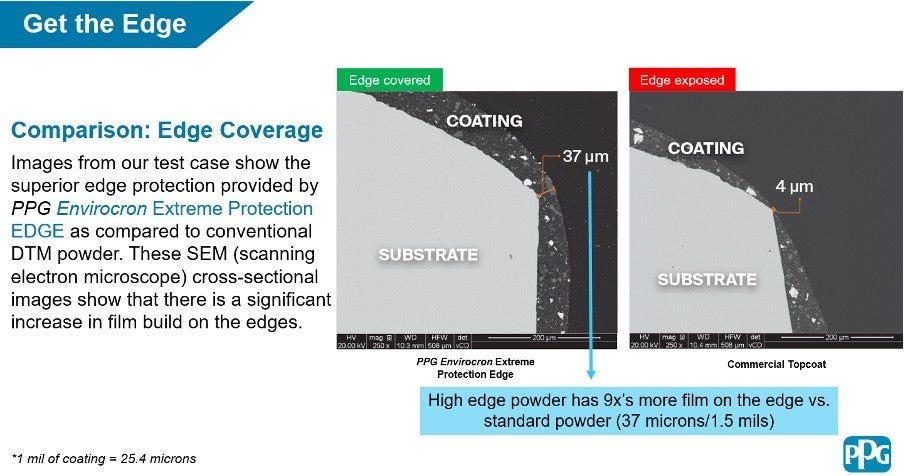

Through the introduction of our ENVIROCRON® Extreme Protection Edge powder coating technology, PPG has solved a long-standing issue of edge coverage.

Until recently, it was difficult for coatings to maintain a layer of protection throughout the curing process on a sharp edge, particularly cut edges on steel. Poor edge coverage would lead to deterioration, with rusting and corrosion along the exposed edges-a significant issue and a prime opportunity for innovation.

Reshaping the Industry

PPG recognized the customer need for a coating that could be applied in one-step, would provide better corrosion protection and have exceptional edge coverage.

For three years, we researched and developed the technology required to produce Envirocron Extreme Protection Edge powder coating. Now in market, our high-edge powder coating exceeds the corrosion protection performance of other available technologies.

While laser cutting is necessary in the production of metal parts, it creates sharp edges that are difficult to pre-treat and coat due to the formation of oxide layers from the cuts. Even after a conventional coating application and cure, these sharp edges essentially remain uncoated and are a point of entry for corrosion to start once they are exposed to the elements.

One solution to improve edge protection has been edge rounding of laser cut parts prior to the coating application. This process, however, comes at a significant cost. Therefore, the introduction of a single-coat powder that can coat laser-cut edges during application, and stay on those edges after curing, is a huge step forward in reshaping the industry.