Dive into the World of Electrocoating

While most consumers are unfamiliar with the electrocoat finishing process, they certainly use products every day that feature a protective or decorative coating that has been applied with the method.

Electrocoating, or e-coating, is a high-performance finishing process that uses an electrical current to deposit paint onto conductive substrates like rolled and galvanized steel, aluminum and cast iron. Valued for its versatility, ecoat can be used as a primer but also as a cost-saving one-coat application.

Electrocoat is a three-step process that starts after substrate cleaning and pretreatment. First, the charged metal part is immersed into a bath of an oppositely charged paint dispersion. The charged paint particles are drawn to the metal part to completely envelop the surface with a continuous film that covers every angle, corner and groove until the desired thickness is achieved. The second step is a closed loop post-rinse where excess paint solids are returned to the tank via ultrafiltration, followed by the third and final step, the curing and hardening of the e-coat film in a thermal oven.

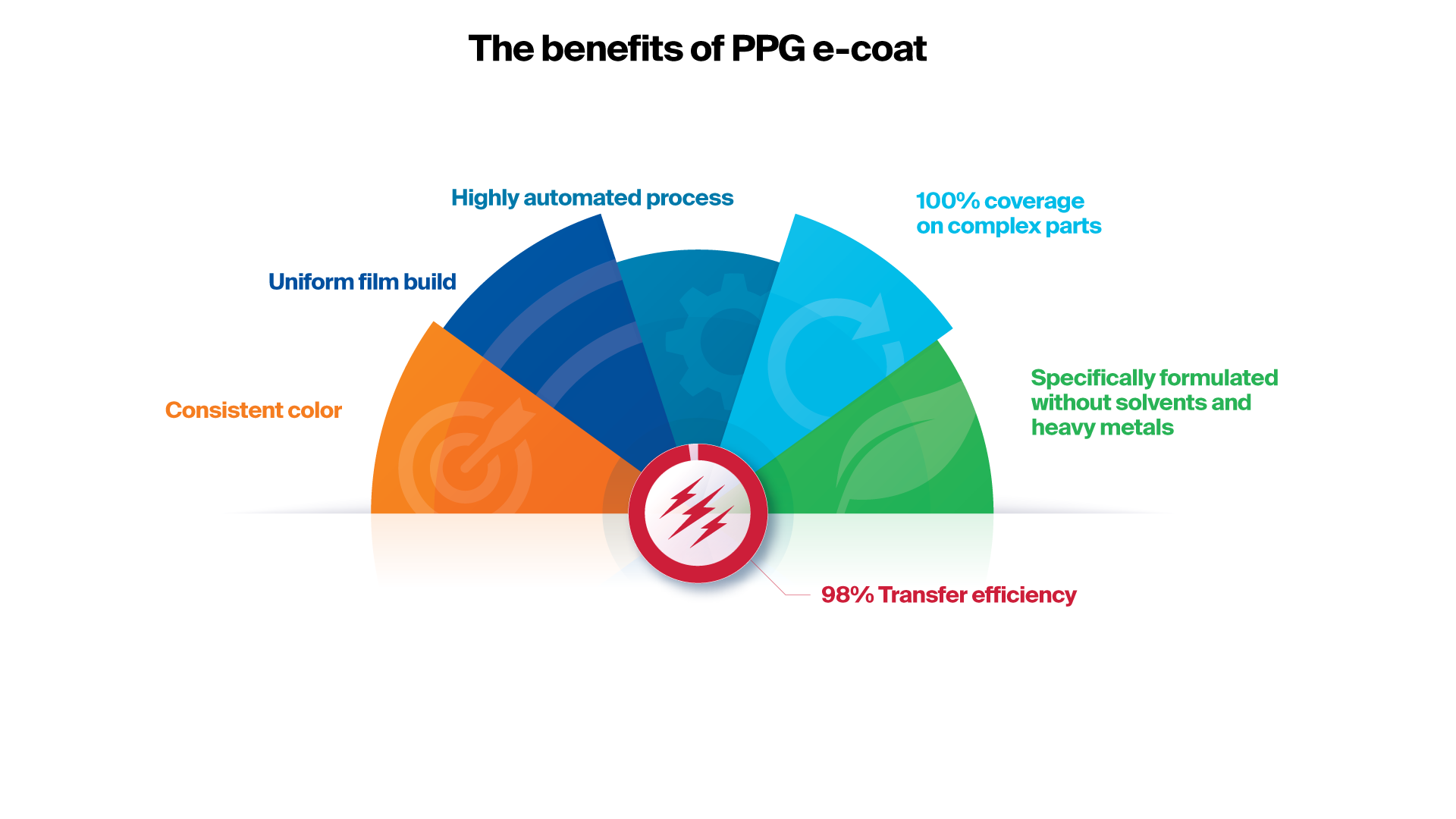

E-coat offers 98% transfer efficiency, color consistency and a uniform film build on parts with complex geometries, making it one of the most efficient coating application methods.

The finishing method is considered to have several sustainability benefits, including the fact that it is an aqueous-based system and generally formulated without solvents.

Other notable advantages of electrocoating include:

- Outstanding corrosion protection performance for extended asset life

- Precision control over film thickness

- Reduced labor needs with highly automated process

- Specifically formulated without heavy metals

Common Applications for Electrocoating

Since the 1970s, electrocoating has been widely used in the automotive industry. Today, cathodic epoxy electrocoat primers are standard for protecting auto parts and accessories, driven by both environmental regulations and performance requirements for corrosion and chemical resistance.

While automotive applications hold the bulk of the e-coat market, the process is also used to protect a wide array of appliances like washers and dryers, ovens and range hoods because it provides excellent corrosion resistance from detergents, as well as gloss, hardness and color.

Other items commonly protected with e-coat include heavy-duty equipment and industrial products such as ventilation air diffusers, shelving and racking, shopping carts, pipe fittings and fencing.

For the fastener industry, electrocoat is valued for its bulk finishing capabilities since it requires no labor to hang small parts and does not fill recessed heads or threads.

PPG Electrocoat Solutions

Since pioneering ecoat in 1963, PPG has been at the leading edge of the technology in the years since.

Our electrocoat portfolio includes the latest product, POWERCRON® 10X™, the newest generation cationic epoxy electrocoat.

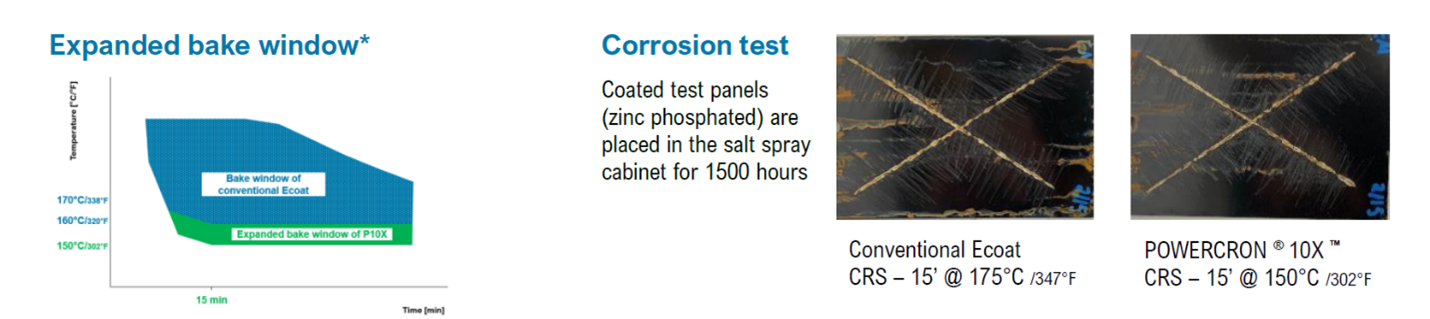

Formulated without a tin catalyst, Powercron 10X offers high-edge coverage on complex shapes and sharp parts, an expanded baking window and high throw power with broad film build capability. Typical applications include automotive parts, frames and truck beds, and heavy duty and agricultural equipment.

Other PPG e-coat products include single-component and high coverage, cationic epoxy formulations approved for use in the automotive industry such as POWERCRON® 6000CX and POWERCRON® 6100 HE.

FRAMECOAT® II high-edge, black cathodic epoxy electrocoat is designed to meet both frame and small complex part specifications.

POWERCRON® acrylics are a wide variety of products that combine corrosion protection and UV durability. These electrocoats are available in multiple colors and gloss options, and are commonly used as a one-coat final finish for interior and exterior parts.

ELECTROPOLYSEAL® e-coat systems were designed for bulk applications like fasteners and other small parts. They will not fill recesses or threads and offer excellent corrosion protection, outstanding adhesion and precise torque control in a range of performance options.

In addition to industry-leading electrocoats, PPG is one of the few global coatings companies with solutions in every major technology—including liquid, powder, pretreatment and ultra-violet and electron-beam curable formulations.

PPG pioneered the electrocoating process in the 1960s. The company developed this innovative technology to improve the efficiency and effectiveness of coating applications, particularly in the automotive industry. PPG's advancements in electrocoating significantly contributed to the widespread adoption of this method, which is now utilized across various industries due to its ability to provide uniform coverage, excellent corrosion resistance and sustainability benefits.