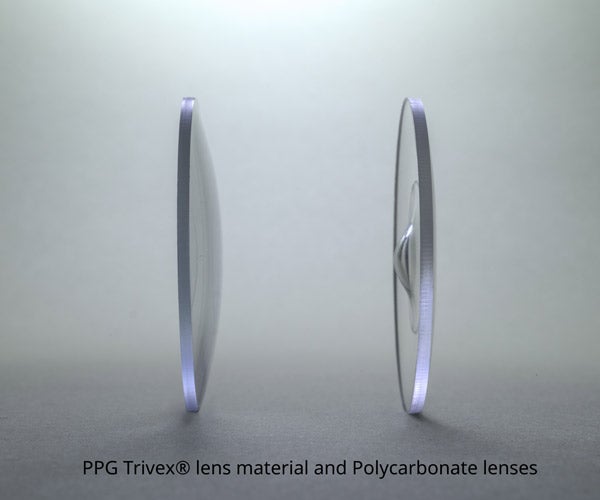

Stringent Testing Shows PPG TRIVEX® Lens Material Outperforms Polycarbonate

Optical performance backed by research

In new research conducted by PPG, HOYA Phoenix® lenses made with PPG TRIVEX® lens material outperformed polycarbonate in various testing categories. Read the full white paper to learn more.

What sets PPG Trivex lens material apart?

PPG Trivex lens material combines optical clarity, impact resistance and lightweight comfort to meet diverse customer needs.

- Impact Resistance*

Lenses made with PPG Trivex lens material demonstrate strong durability in high-impact conditions. Unlike polycarbonate lenses, which showed dimpling during Gardner Impact Tests, HOYA PHOENIX® lenses with PPG Trivex material maintained their integrity, making them an ideal choice to prevent lens damage in everyday wear, and especially suitable for sports eyewear and safety glasses. - Exceptional Optical Clarity

PPG Trivex lens material demonstrates exceptional optical clarity due to its high Abbe value, which reduces the “rainbow blur” that can appear around the edges of lenses, ensuring consistent sharpness across the entire lens. The cast-molding production process reduces birefringence, helping prevent blurriness or distortion. Together, the result is uniform clarity across the lens surface. - Lightweight and Comfortable

With its exceptionally low specific gravity, PPG Trivex lens material offers a lightweight lens option for all-day wear, reducing strain without compromising performance. - Chemical Resistance

Through chemical submersion testing, PPG Trivex lens material was shown to resist damage – including scratches, discoloration and crazing – from common chemicals, helping to support long-term functionality and clarity.

Learn more about HOYA Phoenix® lenses

*Impact resistant lenses are neither shatterproof nor unbreakable. Coatings may alter the impact resistance of any lens material.