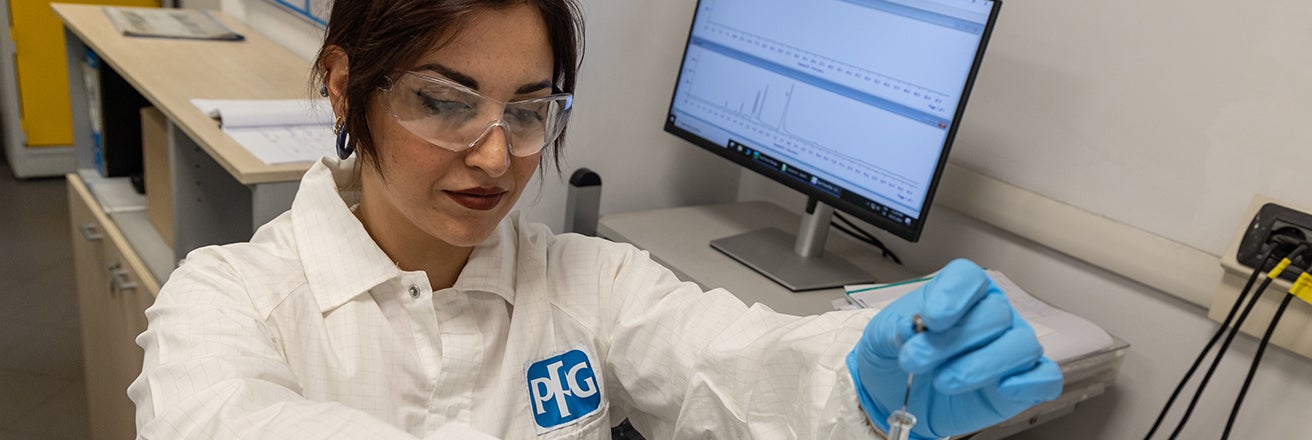

PPG is actively seeking opportunities to reduce our products’ carbon footprint through product innovation. It is important for our scientists and researchers to easily access accurate, consistent and reliable raw material carbon footprint information in order to develop new products with a lower carbon footprint. The PPG Product Sustainability Center of Excellence (COE) continues to enhance our internal cradle-to-PPG gate Product Carbon Footprint (PCF) tool. The PCF tool enables product managers and developers to quickly access and evaluate carbon emissions associated with a product’s raw material composition, the production and processing of those materials, inbound transportation and manufacturing. This PCF tool seamlessly connects with PPG’s product stewardship system, so product developers can leverage improved visibility to design products with lower carbon footprints. Our PCFs are based on industry average emissions data that we will continue to refine to be more precise over time.

In 2023, we received over 1,600 requests for PCF information. In order to respond to our customers’ increasing demands, in 2024, the Product Sustainability COE developed an automated PCF workflow within the PCF tool that enables PPG employees to input basic product information and immediately generate PCF declarations for our customers. This automated process allows us to significantly reduce response times from weeks to days and fulfill a higher volume of PCF requests aligned with customer demand. With faster turn around time and more granular PCFs at an individual product level, customers can feel more confident choosing PPG as their first choice partner on their decarbonization journey, which helps strengthen our relationship with customers for future growth. The tool is also able to break down PCF information by lifecycle stage, delivering more actionable and transparent information to our customers.

Learn more about our work to reduce product carbon footprints in the sustainably advantaged products and energy and emissions sections.

Food contact compliance

PPG's Food Contact Center of Excellence (COE) uses a digital tool to evaluate regulatory compliance in food contact (FC) coating formulations used in cookware and bakeware applications. The tool enables PPG to streamline and automate the process for FC regulatory compliance checks. It also features a robust data collection engine that powers our FC regulatory database by continuously monitoring new and evolving FC regulatory changes globally. By staying ahead of evolving regulation, we are able to meet customer and regulator expectations in the myriad markets where we operate. For example, in 2024 our product stewardship team secured food contact use approval in China for our kitchen and industrial bakeware FUSION™ Pro coating for cookware, resulting in a $2.4 million lift in sales.

Substance of Interest scorecards

Over the course of 2024, we created 18 additional Substance of Interest scorecards (SOI), which track hazards and regulatory requirements. At the end of the year, our product stewardship organization had a total of 227 scorecards tracking 378 substances. SOI scorecards also include carbon footprint information, providing additional data to our formulators and chemists.

Restricted Substances List

PPG’s Restricted Substances List (RSL) is applied to all PPG products globally, even in areas of the world where there are no chemical regulation programs, which means that our RSL program goes beyond regulatory compliance. PPG’s RSL includes all substances covered by the Stockholm Convention on Persistent Organic Pollutants and industrial substances on the Rotterdam Convention Prior Informed Consent list which cover 193 substances.

Based on recommendations from our product stewardship organization, PPG’s Sustainability Committee approved the addition of 101 new substances to the RSL over the course of 2024. PPG’s RSL now includes 1,888 substances that are restricted for all uses, and 491 substances that are restricted for specific uses, such as consumer products. These substances, to the extent utilized at all, will be phased out of existing products and they will not be used in new product development globally moving forward.

In 2024, our Product Sustainability Center of Excellence (COE) collaborated with our toxicology team to develop an automated tool for tracking RSL compliance, which significantly reduced the time required to review our portfolio. We plan to roll out training and implementation support in 2025 to help drive awareness and adoption of the new tool.

United Nations Globally Harmonized System for Classification and Labeling

We continue to assess our products according to the United Nations Globally Harmonized System for Classification and Labeling (UN GHS) for category 1 and/or 2 for hazard warnings on products. Of the products scored globally, 25% were not classified with hazards under UN GHS category 1 or 2. We consciously choose lower hazards, especially in architectural coatings products due to their heavy use in consumer, commercial and residential projects.

For more detailed information about our ongoing approach to product stewardship, including detailed information about our key focus areas and tools that support our work, see the bottom of this page.