Why Proper Maintenance of Aircraft Transparencies Matters

Aircraft transparencies are critical components that directly impact flight safety and operational effectiveness. These surfaces can be made from specialized plastics such as polycarbonate, acrylic or OPTICOR® advanced transparency material and provide pilots with clear visibility while protecting them from environmental hazards. However, due to their exposure to harsh conditions, including UV radiation, airborne debris, bug splatter, and moisture, these transparent materials are prone to developing haze, scratches, water spots and other forms of surface degradation over time.

Maintaining the clarity and integrity of these surfaces is essential not only for pilot visibility but also for the longevity of the aircraft components. Improper cleaning or the use of incompatible polishing compounds can accelerate wear, cause micro-scratches or even damage protective coatings, leading to costly repairs, forfeited product warranties or replacements. Therefore, selecting the right cleaning and polishing products is a vital part of aircraft maintenance protocols.

Aviation windshield cleaners and polishing compounds serve multiple purposes, including:

- Removal of contaminants such as bug debris and water spots

- Reduction of haze caused by environmental exposure

- Restoration of the optical clarity of the surface

- Enhancement of protective properties like water repellency and anti-static effects

Given the fragility and expense of plastic transparencies, it is crucial to use products specifically designed and tested for these materials. This ensures that the cleaning process does not compromise the surface or invalidate manufacturer warranties. In this context, PPG Tex-Whiz aviation windshield cleaner and polishing compound has become a trusted solution, particularly in military and aerospace applications, for its proven effectiveness and compatibility with sensitive plastic substrates.

What is PPG Tex-Whiz cleaner?

PPG Tex-Whiz is a specialized aviation windshield cleaner and polishing compound designed for use on transparent plastic surfaces, whether coated or uncoated. It is formulated as an emulsion that evenly disperses abrasive particles with a narrow particle size distribution. This unique formulation ensures that the abrasive particles remain suspended during application, providing a consistent and controlled polishing action.

PPG Tex-Whiz cleaner is available in different types tailored to specific cleaning and polishing needs:

- Type I features a fine abrasive grit suitable for daily maintenance and light cleaning

- Type II contains a coarser abrasive designed for deeper cleaning and restoration of heavily scratched or hazy surfaces

- PPG also offers a P-P-560 qualified polish variant for general use beyond the F-16 platform

Key Benefits of PPG Tex-Whiz Cleaner

1. Restores and Enhances Transparency

One of the primary benefits of PPG Tex-Whiz cleaner is its ability to restore clarity and luster to aircraft windshields and other transparent surfaces. It effectively removes common contaminants such as bug debris and water spots which can accumulate during flight operations and degrade visibility. The polishing compound also addresses light surface scratches and haze, which can develop over time due to environmental exposure and routine wear.

Unlike many other polishes, PPG Tex-Whiz cleaner polishes off cleanly, leaving no residue behind. This helps ensure that the treated surfaces maintain their optical clarity without any film or buildup that could interfere with visibility or sensor performance.

2. Protects and Helps Extend the Life of Transparencies

Aircraft transparencies are often made from fragile and expensive plastic materials that require careful maintenance to avoid premature degradation. Regular use of PPG Tex-Whiz cleaner not only cleans and polishes these surfaces but also enhances their water-repelling and anti-static properties. These improvements help reduce the accumulation of dirt, moisture and static charges, which can attract contaminants and accelerate wear.

By preserving high optical quality and protecting the surface integrity, PPG Tex-Whiz cleaner helps to extend the operational life of plastic windows and canopies. This longevity translates into cost savings for operators by reducing the frequency of expensive replacements and repairs.

3. High Quality Formulation and Application

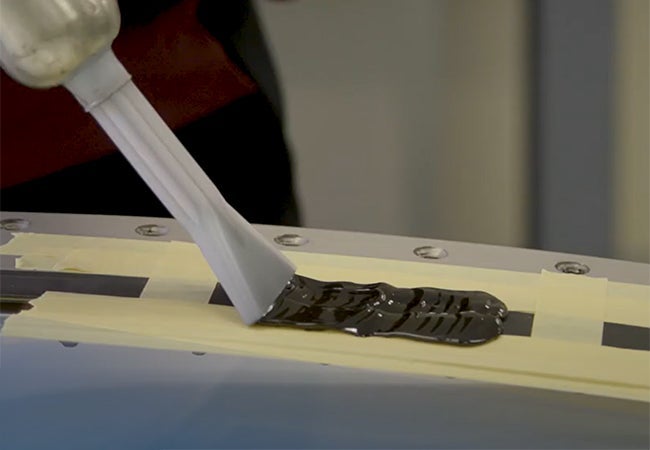

The emulsion-based formula of PPG Tex-Whiz cleaner is a key differentiator that contributes to its exceptional performance. The hydrated alumina abrasive particles are evenly suspended within the emulsion, resulting in a continuous and consistent introduction of abrasives to the surface during polishing. This contrasts with many competitor products that are not emulsions and allow abrasive particles to settle or become unevenly distributed.

When applied with a cloth, abrasive particles remain suspended and lubricated, preventing the cloth from absorbing the liquid portion of the polish. This avoids the common problem of abrasive particles grinding directly against the surface without sufficient lubrication, which can cause scratches and damage.

The result is a polishing process that leaves a pristine shine and luster, improving with repeated use rather than degrading the surface.

4. Compatibility and Safety

A critical advantage of PPG Tex-Whiz cleaner is its specific development for compatibility with PPG’s plastic transparency substrates and external coatings. Plastic transparencies are delicate and costly components. Using an incompatible polishing compound can lead to irreversible damage or invalidate manufacturer warranties.

PPG’s unique position as both a chemical company and a manufacturer of aircraft windows allows it to engineer PPG Tex-Whiz cleaner to meet the exacting requirements of these materials. This ensures that the product is safe to use on military canopies, including all versions of the F-16, and other aircraft transparencies without risk of damage.

The product is also approved by major jet and helicopter manufacturers, underscoring its reliability and effectiveness in demanding aerospace environments.

Product Variants and Their Uses

PPG offers three main variants of PPG Tex-Whiz® polish, each designed for specific applications:

- Type I (PN: 5602261): This variant contains a fine abrasive grit and is approved for normal, everyday use on F-16 canopies. It is ideal for routine cleaning, removing bug debris, water spots and light scratches while restoring surface luster.

- Type II (PN: 5602260): Featuring a coarser abrasive, Type II is intended for deeper cleaning and restoration. It effectively treats more aggressive scratches, swirls and extremely hazy surfaces, making it suitable for surfaces requiring more intensive maintenance.

- P-P-560 Polish (PN: 5602262): Qualified under the P-P-560 federal specification, this polish is equivalent to Type I in abrasive content and is marketed for general use beyond the F-16 platform. It is approved for use by the U.S. Army and U.S. Navy on various aircraft transparencies.

Why Choose PPG Tex-Whiz Polish Over Competing Products?

PPG Tex-Whiz polish stands out in the industry for several compelling reasons:

- Unique Emulsion Formula: Unlike many competitor polishes that are not emulsions, PPG Tex-Whiz polish keeps abrasive particles evenly suspended, resulting in consistent polishing without scratching.

- Proven Military and Aerospace Use: PPG Tex-Whiz is a transparency polish used by major aerospace manufacturers, with approvals for F-16 canopies.

- Compatibility and Warranty Compliance: Specifically engineered for PPG’s plastic transparencies and coatings, PPG Tex-Whiz polish does not risk damaging surfaces or voiding PPG product warranties, a critical consideration for expensive and fragile aircraft components.

- Polishing Results: The product restores optical clarity, removes contaminants and scratches, and enhances protective properties, helping extend the life of transparencies.

- Global Availability and Support: PPG Tex-Whiz polish is available worldwide through PPG’s aerospace application support centers, ensuring customers have access to expert guidance and reliable delivery.

Additional Aerospace Consumables from PPG

PPG Tex-Whiz cleaner is part of a comprehensive suite of PPG aerospace consumables designed to maintain and protect aircraft transparencies. Other products include:

- CLARITY™ Transparency Cleaning System: A cleaning solution for transparent surfaces.

- HYDROSKIP® Advanced Coating Solution: A water-repellent coating that helps enhance visibility in wet conditions.

- SURFACE SEAL® Hydrophobic Coating: A protective sealant for transparency surfaces.

- Hump Seal Repair Kit: For repairing seals on aircraft transparencies.

Together, these products provide a complete maintenance system, with PPG Tex-Whiz cleaner playing a central role in cleaning and polishing.

The Clear Choice for Aviation Transparency Maintenance

Maintaining the clarity and integrity of aircraft windshields and transparent surfaces is essential for safety, performance and cost efficiency in aviation. PPG Tex-Whiz aviation windshield cleaner and polishing compound offers a proven solution that restores transparency, protects delicate plastic surfaces and helps extend operational life.

With its unique emulsion formula, proven military-grade performance and compatibility with sensitive substrates and coatings, PPG Tex-Whiz cleaner is the trusted choice for aviation professionals worldwide. Whether for routine maintenance or deeper restoration, PPG Tex-Whiz cleaner delivers consistent, high-quality results that help keep aircraft transparencies clear and durable.

For those seeking a reliable and effective polishing compound, PPG Tex-Whiz cleaner stands out as the clear choice. Contact us to learn more or to place an order.