Why Choose PPG ARE 3D Printed Sealants

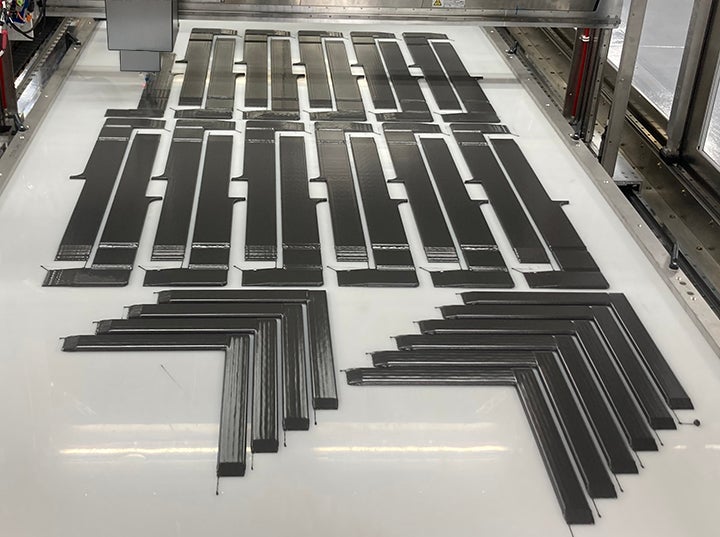

Traditional aerospace gaskets and sealants require extensive manual labor and rework. PPG’s 3D printed polysulfide and polythioether gaskets were created with aerospace engineers and technicians in mind and some have a national stock number (NSN). These preformed sealants eliminate the need to smooth sealant by hand, can be printed and shipped on demand once designed and are proven to save time and reduce costs

PPG’s PRC® and PRO-SEAL™ brand sealants have laid the foundation for aerospace manufacturing, maintenance and repair for the aerospace industry. PPG’s sealants are taking that excellence to the next level through creation of this innovative process that pre-forms sealants. This revolutionary application method improves your sealant application.

- Accelerated Installation Times: Traditional sealant application methods can be time-consuming and labor intensive. With PPG ARE 3D printed sealants, installation times can be reduced by up to 90%. Our automated production process allows for parts to be applied up to 10 times faster than conventional methods, enabling you to meet tight project deadlines without compromising quality.

- Potential Cost Savings: Cost efficiency is a critical factor in aerospace projects. By utilizing our 3D printed sealants, you may achieve cost savings on overall project costs. Our innovative technology minimizes labor and material waste, providing a more economical solution that enhances your bottom line.

- Commitment to Sustainability: At PPG, we understand the importance of environmental responsibility. Our 3D printed sealants are designed to align with modern sustainability priorities, virtually eliminating waste during the production process. By choosing PPG, you are investing in high-quality sealants that support efficient and responsible manufacturing practices in the aerospace industry.

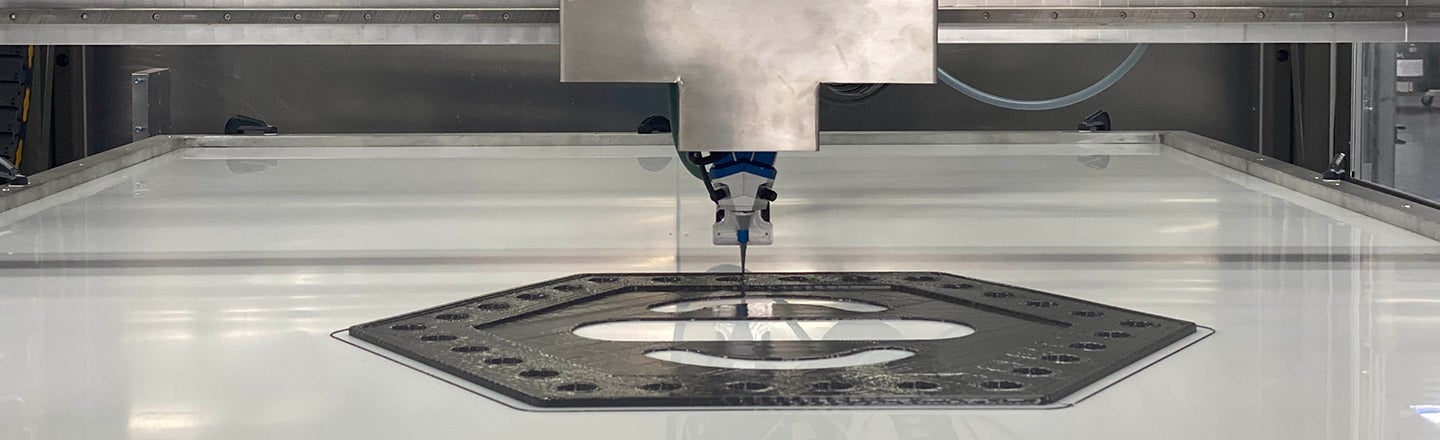

- Unmatched Precision and Quality: Quality assurance is essential in aerospace applications. Our 3D printing technology produces uniform, consistent and dimensionally accurate parts, reducing the need for grinding and rework that his the spec every time. This precision helps ensure that your applications meet the highest safety and performance standards.

Versatile Applications for Diverse Needs

PPG ARE 3D Printed Sealants are engineered for a wide array of aerospace applications, making them an ideal choice for various projects. Our sealants are suitable for:

- Fuel Tanks: Ensure leak-proof performance and safety in critical fuel systems.

- Wing Seals: Enhance aerodynamic efficiency and structural integrity.

- Door and Window Seals: Provide reliable sealing solutions that withstand environmental challenges.

- Thermal Barriers: Protect sensitive components from temperature fluctuations.

- Custom Seal Caps: Tailor-made solutions for unique sealing requirements.

Whether you are involved in aircraft refurbishment, manufacturing or maintenance, our 3D printed sealants are designed to meet your specific needs and exceed your expectations.

Tailored Solutions for Your Unique Projects

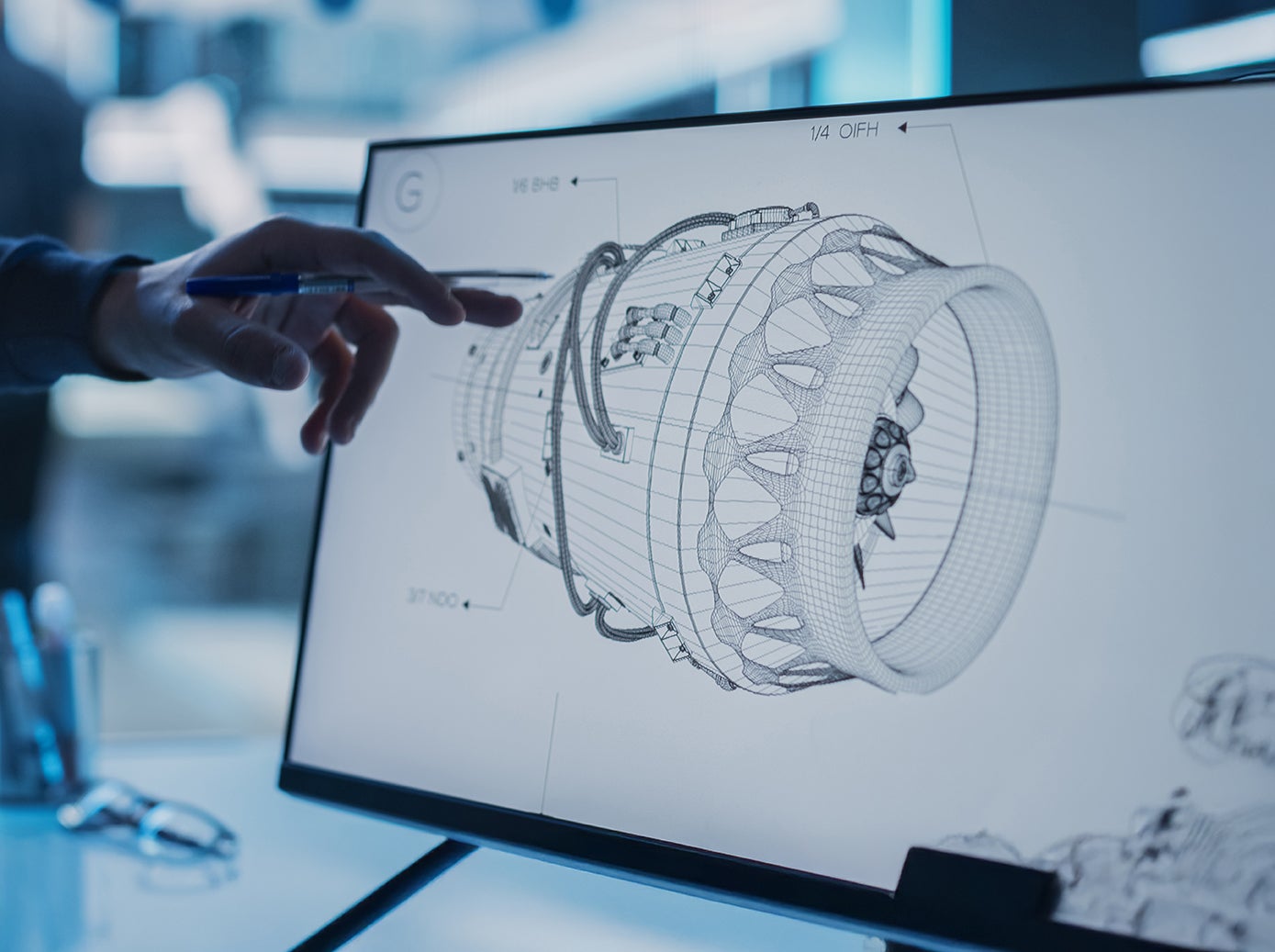

At PPG, we believe in a collaborative approach to innovation. Our team of experts works closely with you throughout the design and production process, ensuring that we create customized solutions that fit your unique requirements. By utilizing advanced technologies such as CAD drawings and laser scans, we optimize part designs for enhanced functionality and performance.